Underground Storage Tanks

About The Project

Underground storage tanks containing jet propulsion fuel are being decommissioned. Regulation requires that the tanks be filled with an inert solid material.

The Solution

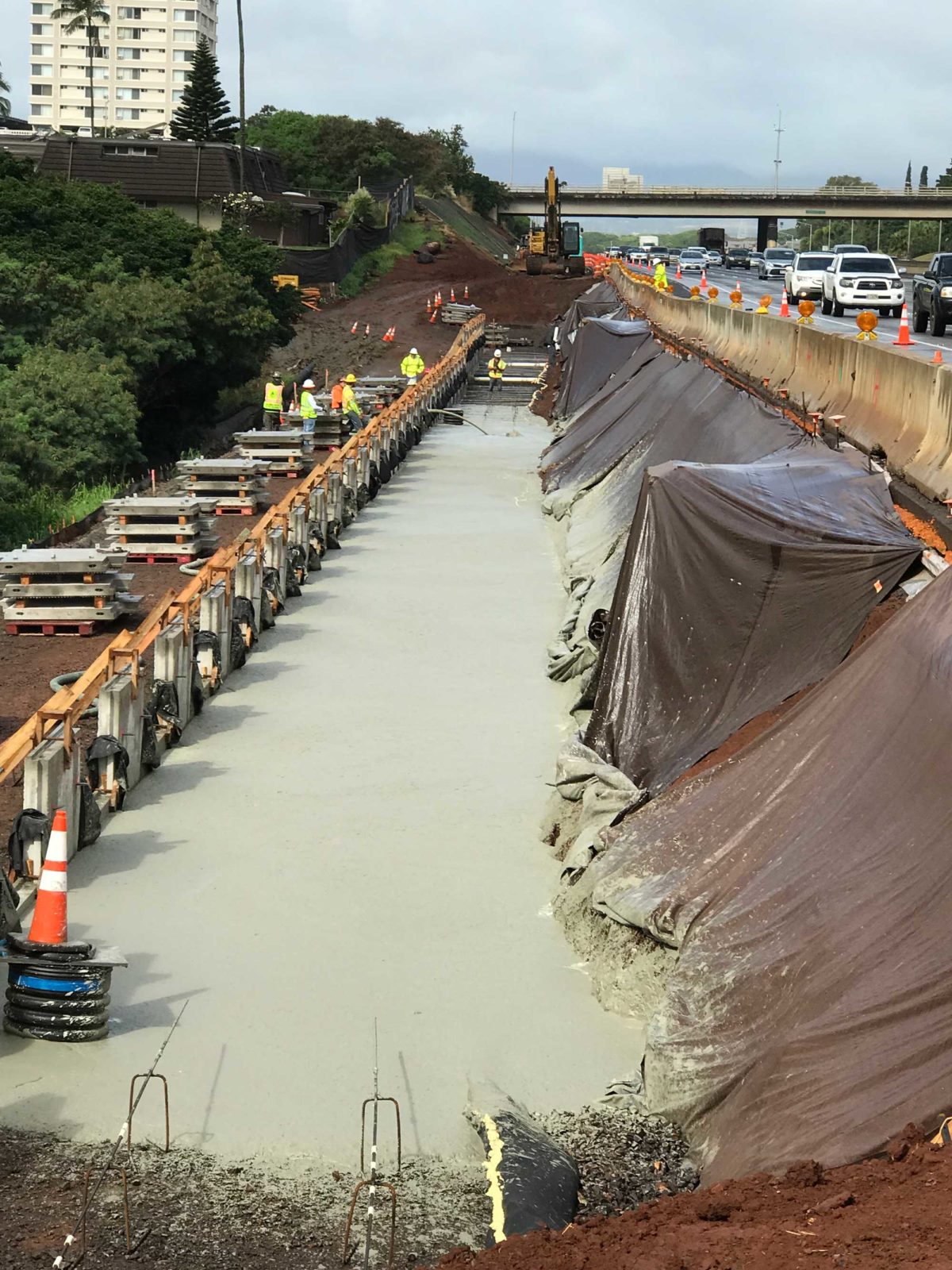

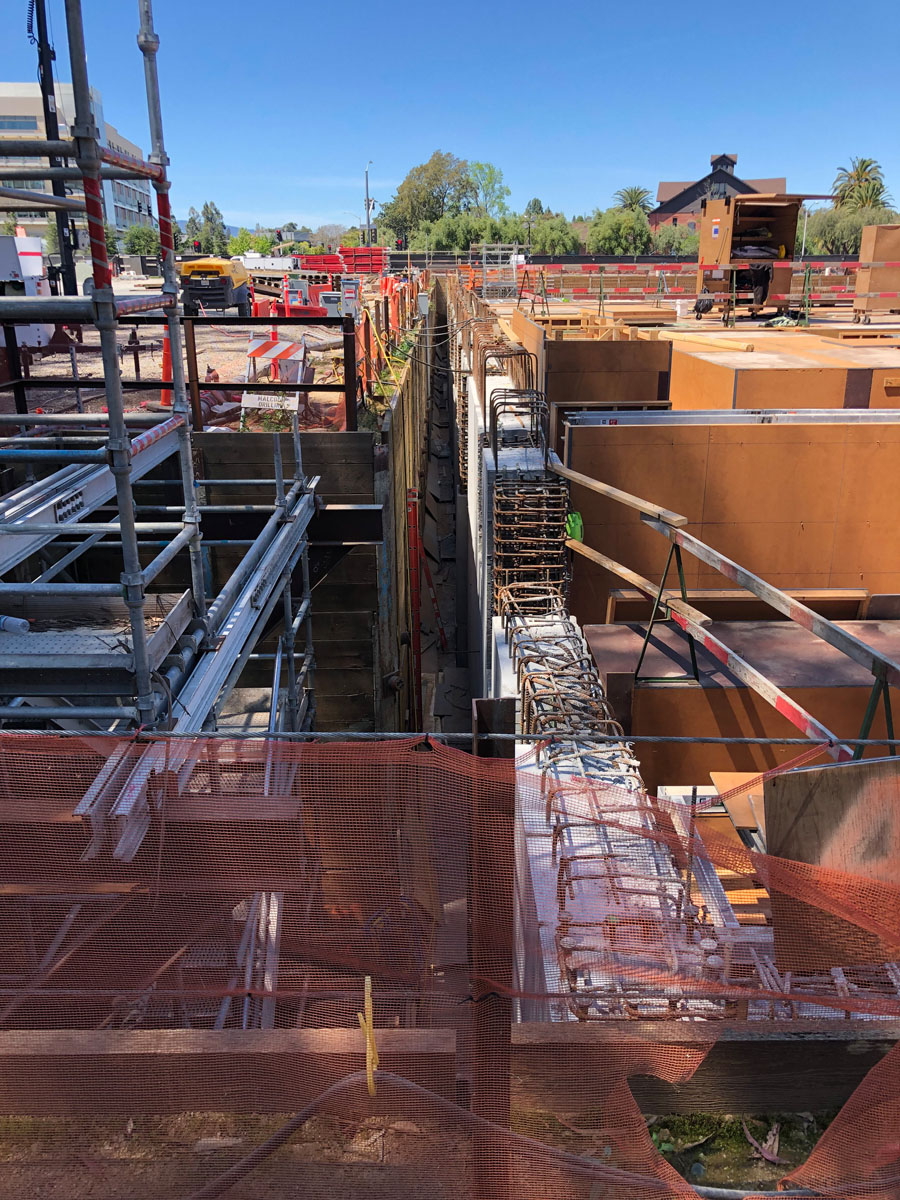

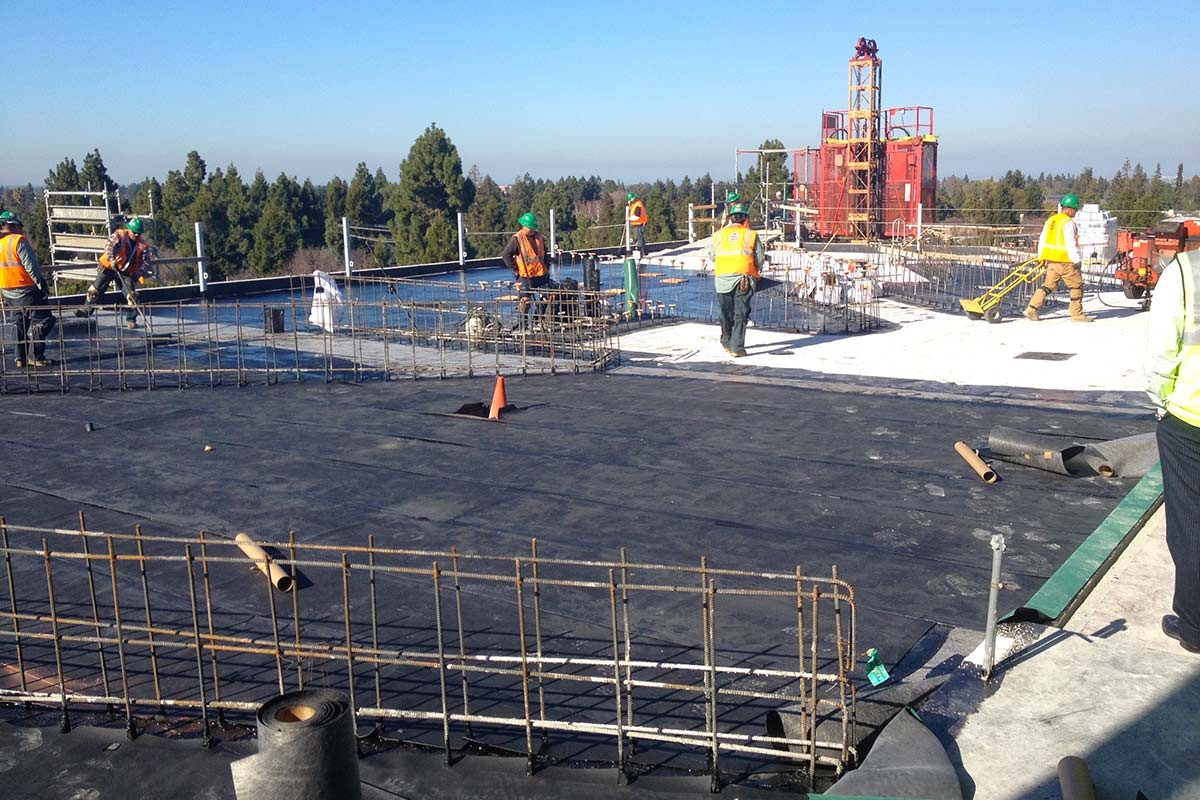

Cellular concrete has been chosen as the backfill material on 3 recent sites—all of which have been completed below budget and ahead of schedule. This material is a wonderful slurry cement product with strength characteristics equivalent to other slurry backfills, such as CLSM, CDF, 2-sack slurry, slurry cement, etc. These product names all refer to ready-mix products where sand is mixed with water and a small amount of cement to create a self–hardening slurry with strengths of around 40 psi. This material provides all these same properties with the added benefits of a highly pumpable/flowable mixture. Due to high volume, the preformed foam that is added to the mixture trucking to the site is minimized. For every truckload of bulk cement we receive for the site, we can produce 120 CY of cellular concrete material compared to 11–12 trucks to achieve the same volume of traditional concrete slurry material.